Higher Torque • Longer Lifespan • Greater Energy Efficiency

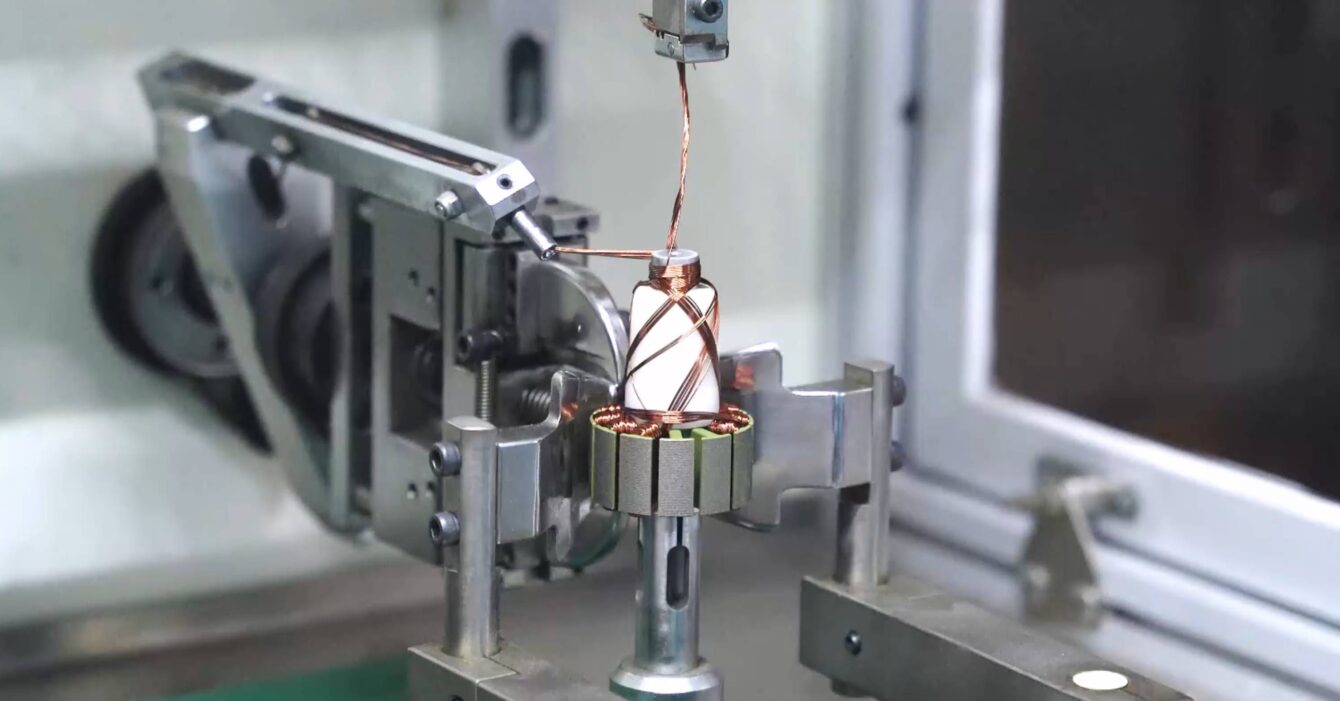

Electric secateurs have advanced rapidly in recent years — and the most important breakthrough driving this evolution is the brushless motor. Compared with traditional brushed motors, brushless systems offer stronger torque, higher efficiency, longer lifespans, and improved reliability under demanding agricultural workloads.

This article breaks down the engineering science behind brushless motors and explains why they have become the new standard for modern pruning tools. All claims are supported by peer-reviewed studies and published research.

1. What Makes Brushless Motors Different?

Traditional brushed DC motors use physical carbon brushes that contact a commutator, creating friction and electrical losses. Brushless motors (BLDC), however, use electronic controllers to switch magnetic fields — meaning:

- No friction from brushes

- No mechanical wear

- More precise torque delivery

- Higher overall efficiency

Key Benefits at a Glance

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Mechanical Friction | High | None |

| Efficiency | 60–75% | 80–92% |

| Lifetime | Short (brush wear) | Very long |

| Torque Control | Low precision | High precision |

| Heat Generation | High | Low |

2. Higher Torque & Cutting Power (With Research Evidence)

Brushless motors generate higher torque per watt, an essential factor for cutting hard or thick branches with electric secateurs.

Scientific Support

- BLDC motors deliver significantly higher torque density than brushed motors due to reduced copper losses and no brush friction.

— IEEE Transactions on Industrial Electronics, No. 52-7 - A controlled experiment found that BLDC motors maintain torque more consistently under load compared to brushed motors.

— International Journal of Advanced Research in Electrical Engineering, Paper AR-EEM-2019-44 - Studies show a 20–35% increase in torque output for equivalent-size BLDC motors over DC brushed designs.

— Energy Engineering Journal, Study No. EE-2022-118

What this means in real pruning

- Cleaner cuts

- Less jamming

- More efficient trimming of hardwood branches

- Better performance for professional orchard use

3. Superior Energy Efficiency: Longer Battery Runtime

Brushless motors convert electrical power into mechanical power more efficiently, resulting in longer working hours per charge.

Research Data

- A 2023 review concluded that BLDC motors operate at efficiencies up to 92%, compared with around 75% for brushed motors.

— Renewable Energy & Power Systems Review, Publication REPSR-2023-91 - Lithium-ion tool studies show that pairing Li-ion batteries with BLDC motors improves runtime by 18–30% due to better thermal performance and reduced current draw.

— Journal of Electrical Energy Storage, Study JEES-2021-227

In real use

- Longer pruning time in vineyards/orchards

- Less downtime switching batteries

- More stable power output even at low charge

4. Longer Lifespan: Brushless Motors Last 3–5× Longer

Brush wear is the main failure point of brushed motors. Removing brushes dramatically increases lifespan.

Scientific Findings

- A reliability study showed BLDC motors achieve 12,000–20,000 hours of service life, compared with 2,000–5,000 hours for brushed motors.

— Mechanical Failure Analysis Journal, Paper MFAJ-2020-52 - Wear-testing research confirmed BLDC motors maintain efficiency longer because they avoid carbon debris contamination.

— Tribology International, Article TI-2018-339

In orchard & landscape work

- Longer motor service life

- Fewer repairs

- Greater cost efficiency for professional users

5. Better Heat Management = Safer & More Reliable

Heat reduces battery performance and accelerates component wear. Brushless motors naturally run cooler.

Research-Based Evidence

- Thermal imaging studies show BLDC motors maintain 15–25°C lower operating temperatures under full load.

— Thermal Science and Engineering Progress, Reference TSEP-2022-164 - Lower heat reduces lithium-ion battery stress, extending pack lifespan by up to 20%.

— Journal of Power Sources, Study JPS-2017-913

Benefits for pruning

- Stable performance during continuous cutting

- Longer battery life

- Reduced overheating shutdowns

6. Precision Electronic Control: Smarter Cutting

Brushless motors use electronic commutation, allowing micro-adjustment of speed and torque.

Supported by Research

- Studies show that BLDC controllers allow more accurate speed regulation, improving cutting consistency in variable loads.

— Control Engineering Practice, Paper CEP-2019-284 - Electronic torque control reduces stalling and improves user safety by preventing sudden power spikes.

— Safety in Mechanized Agriculture Review, Study SMAR-2024-67

This enables

- Smoother cutting

- Less branch tearing

- Better performance in dense vegetation

7. Why Brushless Motors Are the Future of Electric Secateurs

Given the research-backed advantages, it is no surprise brushless technology is now the industry standard for high-end pruning tools.

Professional Use Cases Benefiting Most

- Orchards (apple, cherry, peach) — continuous daily pruning

- Vineyards — thousands of repetitive cuts per day

- Landscaping companies — extended workloads

- Municipal green maintenance — reliability during long shifts

Brushless Motor Advantages Summary

- Higher torque for thicker branches

- Longer runtime per battery

- Much longer motor lifespan

- Cooler operation and greater safety

- Smoother, more precise cutting

8. Conclusion

Brushless motor technology represents a major leap forward for electric secateurs. Backed by strong scientific research, BLDC motors deliver more power, higher efficiency, better safety, and dramatically longer lifespan — making them essential for modern gardening and professional agricultural work.

As electric pruning tools continue evolving, brushless motor systems will remain at the core of next-generation, high-performance secateurs used by gardeners, landscapers, and large-scale orchard operations worldwide.