How Material, Design and Hardness Impact Cutting Performance in Electric Secateurs

1. Introduction

When selecting an electric pruning shear (electric secateur), the blade material is often overlooked — yet it plays a crucial role in cutting efficiency, durability, and suitability for specific plants or branch types. For professionals and serious gardeners alike, choosing the right blade can mean the difference between clean, fast cuts and frequent maintenance or blade replacement. This article explores the key materials (SK5 high-carbon steel, stainless steel, high-speed steel HSS), their mechanical properties, and which scenarios they best fit.

2. Key Blade Materials and Their Characteristics

2.1 SK5 High-Carbon Steel

SK5 is a Japanese equivalent to American 1055 steel, with carbon content around 0.75-0.85% and hardness up to ~65 HRC in heat-treated condition. Academia

In garden-tool applications, many pruning shear manufacturers specify SK5 blades for sharp cutting of green stems and medium wood. For example, product listings mention SK5 high carbon content on their blades.

Advantages: excellent edge retention, very sharp cutting, suitable for branches up to ~20-25 mm in typical home garden uses.

Limitations: less corrosion resistant (requires good maintenance) and may be less suited for very hard, dry wood or abrasive conditions.

2.2 Stainless Steel Blades

Stainless steels offer high corrosion resistance, making them ideal for outdoor, damp, or coastal environments. A comparative study “Wear tests of steel knife blades” found that at ~HRC 61, a particular stainless steel blade out-performed two carbon steels in wear resistance under certain conditions. ResearchGate

Advantages: excellent rust resistance, cleaner cuts when maintenance is difficult, good for soft green growth and frequent garden use.

Limitations: Generally lower hardness and edge‐holding than high-carbon steel, thus may dull faster when cutting harder branches or under heavy load.

2.3 High-Speed Steel (HSS) and Sintered Tool Steels

More rarely used in handheld pruning shears, but referenced in cutting-blade research: a 2023 MDPI study “The Effect of the Surface Topography of High-Speed Steel Cutting Blades…” found that sintered HSS blades had durability up to 1.67× to 1.76× better when cutting structural steel under certain conditions. MDPI

Advantages: extremely durable, high cutting speed performance, lower wear rate — potentially beneficial in heavy-duty agricultural branch cutting.

Limitations: Higher cost, heavier, and possibly overkill for typical garden branches.

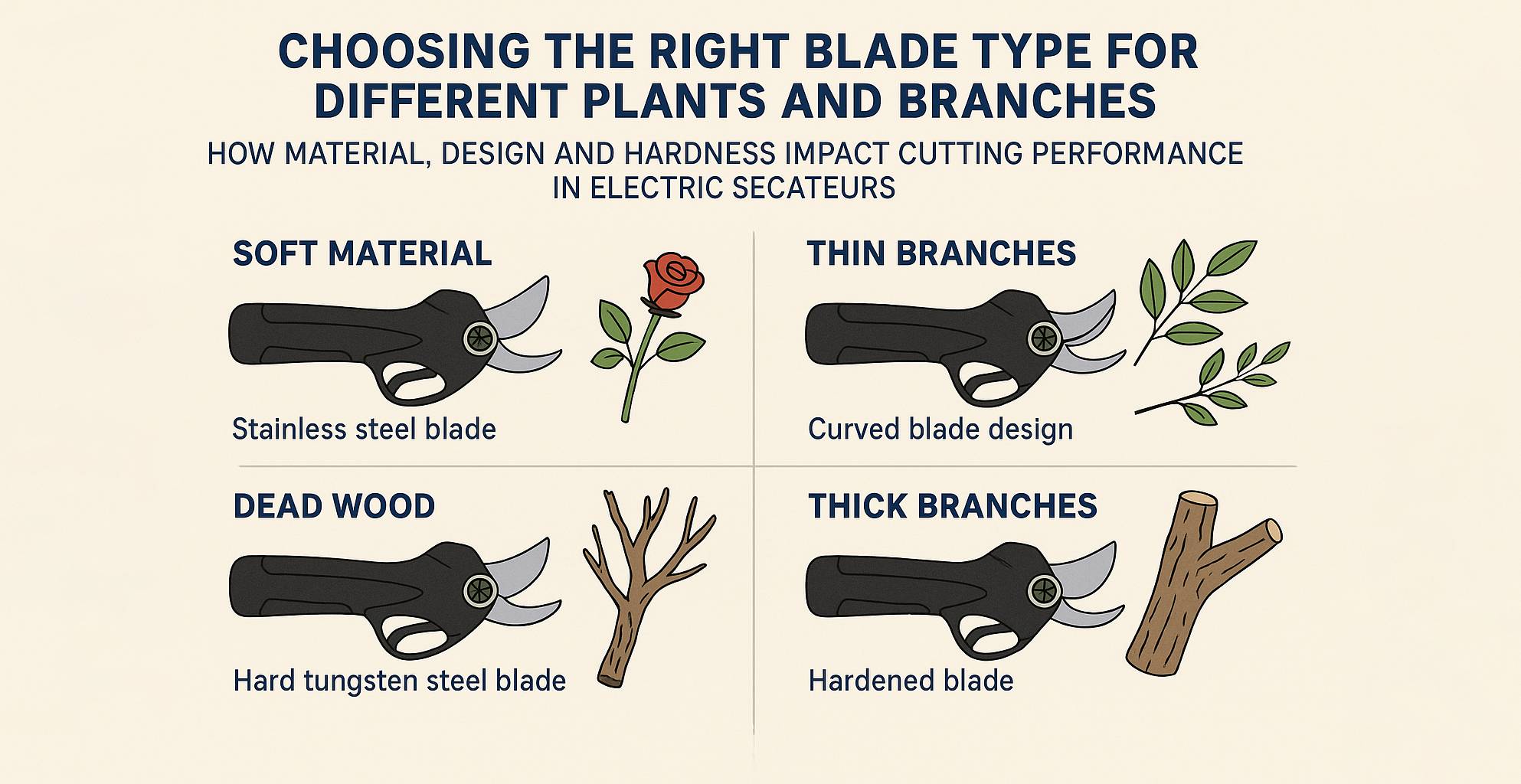

3. Matching Blade Material to Plant Type & Branch Size

| Branch Size & Type | Recommended Material | Rationale |

|---|---|---|

| Soft green stems, frequent cuts | Stainless Steel | Corrosion resistance, frequent maintenance easy |

| Medium woody branches (~10-25 mm) | SK5 High-Carbon | Sharp edge, excellent cut quality, good DIY & semi-pro |

| Hard wood, dense branches (>25 mm) | HSS or premium tool steel | Maximum durability, heavy usage, professional settings |

3.1 Soft growth (roses, shrubs, hedges)

For repeated use in damp or garden environments, stainless steel is often the best balance of durability and maintenance load.

3.2 Medium woody growth (fruit trees, vines)

SK5 high-carbon blades deliver fast, clean cuts with minimal effort, reducing branch trauma and improving tool efficiency.

3.3 Apprentice orchards, large-scale use

If dealing with dense wood, older trees, or high-volume use, HSS or sintered tool steels provide superior wear resistance and longer blade life — lowering total cost of ownership.

4. Additional Considerations Beyond Material

- Blade geometry & bevel angle: Shape of cutting edge influences penetration and branch splitting. A 2024 finite-element study of pruning blades found that designs optimised for reduced cutting resistance improved energy consumption by ~16 – 18% over traditional shapes. MDPI

- Coatings & finish: Teflon or chrome coatings reduce sap build-up and friction (e.g., product info on SK5 blades mentions Teflon non‐stick layer).

- Maintenance requirements: High-carbon steel demands regular cleaning, lubrication and sharpening to maintain performance; stainless is more forgiving but may require more frequent edge re-sharpening under heavy use.

- Tool compatibility: Ensure the blade type is compatible with your electric secateur’s motor and hinge design — using a heavy blade on a light-duty tool reduces efficiency.

- Replacement & spare parts: For pro users, availability of replacement blades is essential to minimise downtime.

5. Practical Buying Guide & Maintenance Tips

- Choose SK5 or high-carbon if you cut 25 mm or less and want sharp, efficient performance.

- Choose stainless steel blades if your environment is very wet, or you do many small cuts daily.

- Consider tool-steel (HSS) if you are a high-volume commercial user needing long-lifetime blades.

- Maintain proper sharpening: Many blades will dull significantly after 50–100 cuts of hard wood; regular edge maintenance improves lifespan and prevents unnecessary motor strain.

- Keep blades clean and oiled; in damp conditions, preventing rust improves durability.

6. Conclusion

The blade material in your electric secateur is not just a minor detail — it impacts cut quality, durability, maintenance frequency, and ultimately cost of ownership. By understanding the differences between SK5 high‐carbon steel, stainless steel, and HSS/tool steels, you can choose the right blade type for your plants, branches and usage scenario.

For brands, engineers and end users alike, aligning blade material with application ensures smoother pruning, less waste, and longer tool life.